- Consulted 200 + BIS Registrations

- Free Experts Assistance

- Minimum Price guaranteed

- Quick and Hassle-Free Process

- Free Consultation on Import-Export Compliance

- 20 years experience & Serving more than 1100+ companies

- Providing one stop solution for all Annual compliances

CONTACT US

Our advisor is just a call away

BIS Product Certification

In accordance with the BIS (Conformity Assessment) Regulations, 2018, BIS (Conformity Assessment) Scheme – I grants licenses to use standard marks or certificates of conformity. Through Product Certification Schemes of BIS, customers are assured of the quality, safety, and reliability of their products. By displaying the BIS certification mark, also known as the Standard Mark, a product can be assured that it complies with required specifications. Following an assessment of conformity to the Standard, the manufacturer can self-certify the manufactured products at his/her factory.

Despite the fact that the program is voluntary, the Government of India has issued orders under various acts from time to time, enforcing compulsory certifications on a variety of products based on public safety, security, infrastructure requirements, and mass consumption considerations. As a result of these orders, manufacturers are required to obtain certification from the Bureau of Indian Standards (BIS) in order to ensure product quality and safety. This ensures that the consumers are buying safe, reliable, and standard-compliant products.

BIS Certification for footwear

On October 27th, 2020, the Department of Promotion of Industry and Internal Trade (DPIIT) notified that all footwear manufacturers, that they would be required to obtain a BIS Certificate for footwear and that all footwear must conform to the applicable Indian Standards and be licensed to carry the Standard Mark (ISI Mark), which should come into effect before the below mandated date July 1, 2023, after which no manufacturer can deal in the same. Without the ISI Mark, leather and other material-based footwear would be illegal to manufacture and sell. This order prohibits manufacturers from producing footwear without a BIS certificate. In the event that you fail to do so, you will be charged with a criminal offense, and you will have to face imprisonment and hefty fines.

Foreign manufacturers, i.e. manufacturers outside India can also secure BIS license through FMCS (Foreign Manufacturers Certification Scheme) of BIS. From July 1, 2023 ,footwear carrying containers won’t be released by customs without a BIS license

It is a MANUFACTURER CONCERNED LICENSE only and not meant for retailers, importers etc. and is APPLICABLE ONLY TO THE FINISHED PRODUCTS.( also footwear soles are considered as a finished product according to BIS guidelines )

Mandatory Dates-

- Medium and Large Scale Industries- Before July 1, 2023

- Small Scale Industries- Before January 1, 2024

- Micro Industries- Before July 1, 2024

Orders for quality control on footwear

There have been three quality control orders issued by BIS pertaining to rubber/polymeric footwear, leather footwear, and PPE footwear in the mandatory certification program.

Three QCOs are listed below:

- (Quality Control Order) 2020 for Leather and other Materials Footwear

- All-rubber and polymeric footwear (Quality Control) Order, 2022

- (Quality Control) Order, 2020 for Personal Protective Equipment – Footwear

BIS Certification for Rubber and Polymeric Material Footwear:

In the order ‘Footwear made from all-Rubber and all-Polymeric material and its components (Quality Control Order, 2022),’ are embedded products such as rubber microcellular sheets, PVC sandals, all rubber gumboots and ankle boots, industrial and protective rubber knee and ankle boots, rubber slippers, rubber Hawai chappals, and PVC industrial boots.

As part of this certification order, all rubber and polymeric materials used in footwear will be subjected to quality control standards.Footwear made from all rubber and all polymeric materials (Quality Control) Order, 2020 lists different types of footwear, their standards, and the name of the standard.

| Sr. No. | Name of Footwear | Indian Standard | Title of Indian Standard |

|---|---|---|---|

| 1 | Industrial and protective rubber knee and ankle boots | IS 5557: 2004 | Industrial and protective rubber knee and ankle boots – Specification |

| 2 | All rubber gum boots and ankle boots | IS 5557 (Part 2): 2018 | All rubber gum boots and ankle boots: Part 2 occupational purposes |

| 3 | Moulded solid rubber soles and heels | IS 5676: 1995 | Moulded solid rubber soles and heels- Specification |

| 4 | Rubber microcellular sheets for soles and heels | IS 6664: 1992 | Rubber microcellular sheets for soles and heels- Specification |

| 5 | Solid PVC soles and heels | IS 6664: 1992 | Rubber microcellular sheets for soles and heels- Specification |

| 6 | Solid PVC soles and heels | IS 6719: 1972 | Specification for solid PVC soles and heels |

| 7 | PVC sandal | IS 6721: 1972 | Specification for PVC sandal |

| 8 | Rubber HawaiChappal | IS 10702: 1992 | Rubber HawaiChappal- Specification |

| 9 | Slipper, rubber | IS 11544: 1986 | Specification for slipper, rubber |

| 10 | Polyvinyl chloride (PVC)industrial boots | IS 12254: 2021 | Polyvinyl chloride (PVC)industrial boots – Specification |

| 11 | Polyurethane sole, semirigid | IS 13893: 1994 | Polyurethane sole, semirigid- Specification |

| 12 | Unlined moulded rubber boots | IS 13995: 1995 | Unlined moulded rubber boots – Specification |

| 13 | Moulded plastic, footwear-Lined, Unlined Polyurethane, boots for general industrial use | IS 16645: 2018 | Moulded plastics footwear- Lined or Unlined polyurethane boots for general industrial use- Specification |

| 14 | Footwear for men and women for municipal scavenging work | IS 16994: 2018 | Footwear for men and women for municipal scavenging work |

BIS Certification for Leather Footwear and Other Footwear Compounds:

“Footwear made from leather and other materials (Quality Control) Order, 2020” covers boots, safety shoes, canvas boots with rubber soles, canvas shoes with rubber sole, sports footwear, Derby shoes, and anti-riot shoes. In the table below, you will find a description of the types of footwear, their standards, and name of the standard referred to in the order.

| Sr. No. | Name of Footwear | Indian Standard | Title of Indian Standard |

| 1 | Leather safety boots and shoes | IS 1989 (Part 1): 1986 | Specification for leather safety boots and shoes Part 1 for miners Specification for leather safety boots and shoes Part 2 for heavy metal industries |

| 2 | Canvas Shoes Rubber Sole | IS 3735: 1996 | Canvas Shoes, Rubber Sole- Specification |

| 3 | Canvas Boots Rubber Sole | IS 3736: 1995 | Canvas Boots, Rubber Sole- Specification |

| 4 | Safety Rubber Canvas Boots for Miners | IS 3736: 1995 | Safety Rubber Canvas Boots for Miners- Specification |

| 5 | Leather safety footwear having direct moulded rubber sole | IS 11226: 1993 | Leather safety footwear having direct moulded rubber sole-Specification |

| 6 | Leather safety footwear with direct moulded polyvinyl chloride (PVC) sole | IS 14544: 1998 | Leather safety footwear with direct moulded polyvinyl chloride (PVC) sole – Specification |

| 7 | Sports footwear | IS 15844: 2010 | Sports Footwear- Specification |

| 8 | High ankle tactical boots with PU – Rubber sole | IS 17012: 2018 | High ankle tactical boots with PU – Rubber Sole – Specification |

| 9 | Antiriot shoes | IS 17037: 2018 | Antiriot shoes – Specification |

| 10 | Derby shoes | IS 17043: 2018 | Derby shoes – Specification |

BIS Certification for PPE Footwear:

There is an Order for the Quality Control of Personal Protective Equipment Footwear, 2020, which covers personal protective equipment footwear.

| Name of Footwear | Indian Standard | Title of Indian Standard |

| Personal Protective Equipment – Footwear | IS 15298 (Part 2): 2016 IS 15298 ( Part 3) : 2019 IS 15298 (Part 4) :2017 |

Personal protective equipment – Part 2 Safety Footwear Personal protective equipment – Part 3 Protective Footwear Personal protective equipment – Part 4 Occupational Footwear |

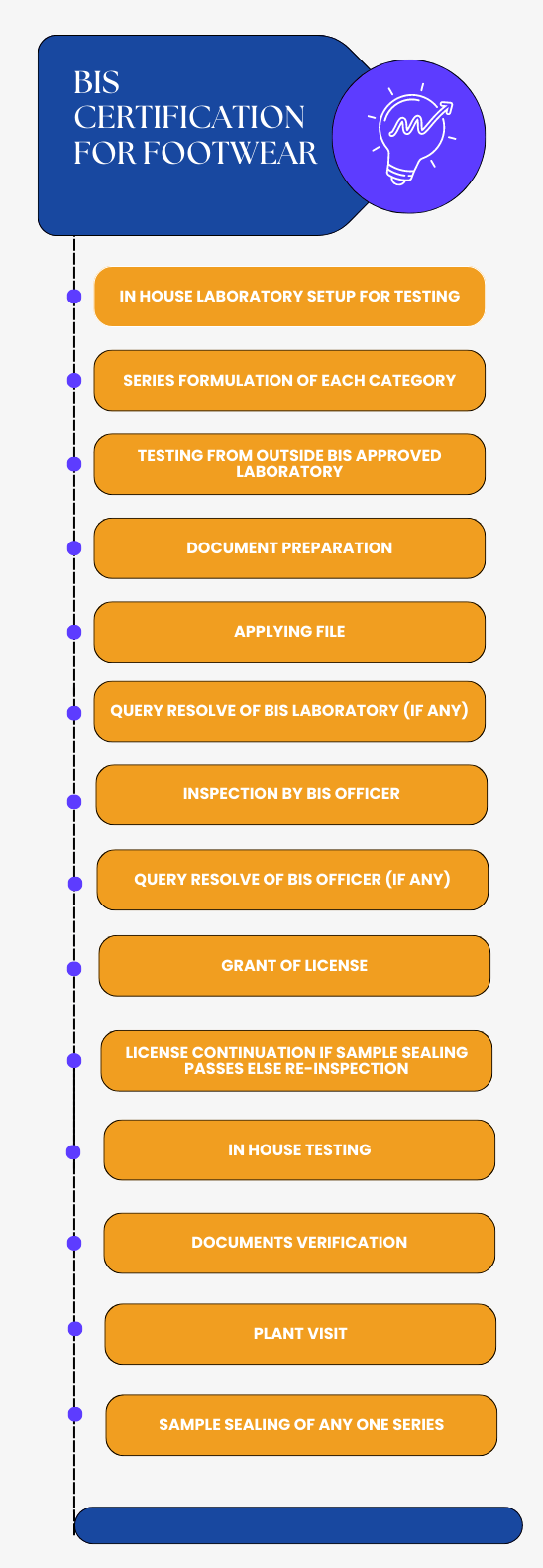

How to obtain BIS certification for footwear?

As per the Quality Control Order for Footwear Products issued by DPIIT, 27 footwear products are now subjected to BIS registration requirements. Before proceeding, you must identify the Indian Standard for your product. It specifies the manufacturing and testing facilities, as well as the product requirements. Make sure you have these facilities and that your product meets these requirements.

Documents Required For BIS Registration For Footwear

- Factory Registration Documents and information

- Layout of Plant (Rough drawing of placement of machinery, lab in plant)

- List of Machinery (as per format)

- List of Testing Equipment (as per format)

- List of Raw Materials (as per format)

- Brand Details (copy of Trademark application)

- Plant Address proof

- Business Licence

- QCI Documents: Qualification Certificate & Identity Proof

- Process Flow Chart (Process from raw materials to finished product)

- Identity Proof of business owner

- Calibration Certificates

- Latest In House Factory Test Report

Validity Period

BIS Certificate comes with a validity of 1 year and needs to be renewed each year.

Fee Structure(Total Expenses Incurred in Obtaining BIS Certificate)

- Lab Setup Cost (In-House)

- Testing Charges by BIS authorized Laboratory

- Government Fees (DOMESTIC)

- Application Fees – Rs 1000

- Annual Fees – Rs 1000

- Inspection Charges – Rs 7000*Minimum Marking Fees – As Per Indian Standards (Royalty Fees) (list below)

- Advisory and Service Charges

Timeline

- Domestic Manufacturer – 30 to 45 days (ISI Certificate)

- Foreign Manufacturer – 3 to 4 months (FMCS Certificate)

Indian Standard for Footwear Products

| IS STANDARD | PER UNIT | LARGE SCALE | SMALL AND MEDIUM SCALE | MICRO SCALE(50% of LARGE SCALE) | UNIT |

|---|---|---|---|---|---|

| IS 10702:2023 | 0.1 / UNIT FOR ALL UNIT | 71000 | 57000 | 35500 | 1 PAIR |

| IS 15844 (PART 1) 2023 | 0.2 / UNIT FOR ALL UNIT | 124000 | 100000 | 62000 | 1 PAIR |

| IS 1989 (PART 1) 2021 | 0.5 / UNIT FOR ALL UNIT | 67000 | 54000 | 33500 | 1 PAIR |

| IS 3735 : 2021 | 0.36 / UNIT FOR ALL UNIT | 121000 | 97000 | 60500 | 1 PAIR |

| IS 3736 : 2021 | 1.2 / UNIT FOR ALL UNIT | 72000 | 58000 | 36000 | 1 PAIR |

| IS 3976 : 2018 | 0.95 / UNIT FOR ALL UNIT | 147000 | 118000 | 73500 | 1 PAIR |

| IS 5557 (PART 2) 2018 | 0.8 / UNIT FOR ALL UNIT | 95000 | 76000 | 47500 | 1 PAIR |

| IS 11226 : 1998 | 0.54 / UNIT FOR ALL UNIT | 46000 | 37000 | 23000 | 1 PAIR |

| IS 5557 (PART 2) 2018 | 0.8 / UNIT FOR ALL UNIT | 95000 | 76000 | 47500 | 1 PAIR |

| IS 12254 : 2023 | 0.44 / UNIT FOR ALL UNIT | 69000 | 56000 | 34500 | 1 PAIR |

| IS 14544 : 2022 | 0.65 / UNIT FOR ALL UNIT | 65000 | 53000 | 53000 | 1 PAIR |

| IS 17012 : 2018 | 0.45 / UNIT FOR ALL UNIT | 203000 | 163000 | 163000 | 1 PAIR |

| IS 17861 : 2022 | 1.5 / UNIT FOR ALL UNIT | 147000 | 118000 | 118000 | 1 PAIR |

The BIS certification for footwear products includes 27 Indian Standards.

| 1. | IS 5557: 2004 | Industrial & protective rubber knee & ankle boots |

| 2. | IS 5557 (Part 2): 2018 | All rubber gum boots as well as ankle boots |

| 3. | IS 5676: 1995 | Moulded solid rubber soles & heels |

| 4. | IS 6664: 1992 | Rubber microcellular sheets for heels& soles |

| 5. | IS 6719: 1972 | Solid PVC heels & soles |

| 6. | IS 6721: 1972 | PVC sandal |

| 7. | IS 10702: 1992 | Rubber Hawai Chappal |

| 8. | IS 11544: 1986 | Slipper, rubber |

| 9. | IS 12254: 1993 | Polyvinyl chlorideindustrial boots |

| 10. | IS 16645: 2018 | Moulded plastics footwear- Lined or Unlined polyurethane boots meant for industrial use |

| 11. | IS 16994: 2018 | Footwear for municipal scavenging work |

| 12. | IS 1989 (Part 1): 1986 | Leather safety shoes & boots for miners |

| 13. | IS 1989 (Part.2): 1986 | Leather safety shoes& boots for heavy metal industries |

| 14. | IS 3735: 1996 | Canvas Shoes Rubber Sole |

| 15. | IS 3736: 1995 | Canvas Boots Rubber Sole |

| 16. | IS 11226: 1993 | Leather safety footwear outfitted with direct moulded rubber sole |

| 17. | IS 14544: 1998 | Leather safety footwear outfitted withdirect moulded PVC sole |

| 18. | IS 15844: 2010 | Footwear meant for sporting activities |

| 19. | IS 17012: 2018 | High ankle tactical boots with Rubber-PU sole |

| 20. | IS 17037: 2018 | Antiriot shoes |

| 21. | IS 17043: 2018 | Derby shoes |

| 22. | IS 15298 (Part 2): 2016 | Personal protective equipment (PPE) – Part 2 Safety Footwear |

| 23. | IS 15298 ( Part 3) : 2019 | Personal protective equipment – Part 3 Protective Footwear |

| 24. | IS 15298 (Part 4) : 2017 | Personal protective equipment – Part 4 Occupational Footwear |

| 25. | IS 3976:2003 | Safety rubber boots made for miner |

Importance of ISI mark

The ISI mark is mandatory since it demonstrates that the product (Footwear) is up to BIS standards. Safety is a major concern in this situation. It is essential for a person to wear shoes that are safe, comfortable, and can protect him or her from various dangers. As such, you can see how important ISI marks are for footwear. ISI Mark assures the consumer about the product’s safety and quality, hence it becomes a major marketing tool for your product. Also, when we talk about footwear, ISI Certification is mandatory, hence each manufacturer needs to secure BIS license prior to its production.

Why Choose Us?

In order to obtain BIS certification for any product, a complex and elaborate process must be followed, starting with product development and validation, and concluding with BIS certification. In case of BIS registration for footwear, an expert will be able to save you a great deal of time, money, and resources.

For all types of footwear, Global Solution provides full technical assistance for BIS certification. With Global Solution’s team of experts, you are assured of a high level of compliance with regulatory requirements. The BIS certification process is guided and assisted by our professional staff from start to finish. Our office is located in the North of Delhi and we serve clients across the country and abroad. Several countries around the world have been served by us, including several top-rated companies.

Conclusion

In conclusion, BIS Certification plays a crucial role in the footwear industry by ensuring the safety, quality, and compliance of products. By obtaining BIS for footwear, manufacturers can establish consumer trust, gain access to domestic and international markets, and protect their brand reputation. Certification is challenging, but it comes with many benefits.It is essential for manufacturers to understand the requirements, comply with the standards, and follow the necessary steps to obtain BIS Registration for their footwear products.

Contact us at 9990899620 or send an email to footwear@globalsolution.co.in for more details on the BIS Registration for footwear and to operate your business efficiently. To match your expectations, we’ll offer rapid and effective BIS Registration for footwear. Our professionals will assist you in completing the BIS registration procedure step-by-step, ensuring that you receive your BIS certificate on time.

Our Partners

We believe to build a strong network of clients and to serve the eco-system with mutual benefits. Some of our esteemed clients are: